This beginner’s guide to reloading will help you get started with the right gear and general process

Around 2015, there was an ammo shortage. I got my first hint just before deer season. I went to the gun store to pick up a box of .30/06 and saw nothing but empty shelves. There were a few dusty boxes of .375 H&H and .416 Rigby, and I briefly considered buying an elephant gun to hunt deer that fall, but then I noticed another shelf, a few aisles over, chock full of reloading gear. The ammo was gone, but that didn’t really matter if I could make my own.

Over the next couple months, I lived between my reloading bench and the range. I could shoot as much as I wanted as long as I had enough powder, bullets, and primers. I was also having just as much fun making my own ammo as I was shooting it.

No matter what your reason is for getting into reloading, you’ll probably find that it adds something to the experience of shooting a rifle, handgun, or shotgun. Maybe it’s because you’re more involved in the process, or maybe it’s because you feel more self-reliant knowing that you don’t always need to buy ammo in a store. If you’re just getting started, or planning to buy your first press, here’s a breakdown of what to expect.

A caliper is an essential tool for reloading ammunition. All images by Matthew Every

REASONS FOR RELOADING

If you’re reloading to save money, you’ll be a little disappointed. After considering the tools, time, and cost of components, it may take some time for you to recoup your investment. And if you’re reloading to shoot in bulk, you can generally buy bulk ammo for common calibers cheaper than you can reload it. There are some exceptions, though.

The first is when reloading premium hunting ammo. High-end ammo can cost $50, $60, or even $75 per box. If you roll your own, you can save a bit of cash. Another cost-saving would be for obscure and antique cartridges. For example, you’ll have better luck making your own .38-55 ammo than finding it in a store for a reasonable price.

Don’t Miss: Hunting with the Federal 7mm Backcountry

Aside from saving money, people get into reloading mostly to tailor a cartridge to shoot better out of their rifle. All rifles like different kinds of ammo, and by reloading, you can tune a cartridge and make your rifle shoot better. It takes some experimenting, but it can be done.

Maybe the biggest reason people start reloading is because it’s fun. If you like to tinker with things, or want to learn more about how cartridges and guns work, you should give reloading a try. You can just scratch the surface and make a few hunting or target rounds for the range, or you can go really deep, reloading ammo for precision shooting, casting your own bullets, and even creating your own “wildcat” cartridges and custom-cut chambers.

CARTRIDGE BASICS

The four basic components of a centerfire cartridge include the primer, the brass shell casing, the powder charge, and the bullet.

To better understand reloading, it helps to understand how a metallic cartridge works. You can break any metallic cartridge down into four components: The brass shell casing, the primer, the powder charge, and the bullet. The shell casing is what holds everything together, and it’s the only part of a cartridge that’s reusable after you pull the trigger. Reloaders either re-purpose spent shell casings to make new ammo or start fresh with new brass to make custom ammo.

The shell casing has a pocket and hole drilled at its base to hold a primer, a cavity of space inside for the powder, and a case neck that holds the bullet. The primer is what a gun’s firing pin strikes to make the cartridge fire.

Don’t Miss: The Top Cartridges for Giant Bucks, According to B&C Statistics

The powder charge is what will drive your bullet down the barrel. Powder is measured in grains. After the primer goes off, it ignites the powder, causing an explosion. There are a dizzying number of powders out there, and it’s extremely important to follow a reloading manual to the letter to figure out which powder goes with your cartridge.

Bullets are pretty self-explanatory. Sending one downrange is what all of this reloading is for. Bullets are also measured for weight in grains and in diameter by caliber. At first, understanding bullet designations can be confusing, because some may not seem like they match the cartridge you’re reloading for. (For example, a .44 Magnum cartridge takes a .429-caliber bullet.) They also come in different weights, which can wildly affect your point of impact on target. But experimenting with things like bullet weight—with published load data, of course—is part of the fun of reloading.

YOUR FIRST PRESS AND NEEDED TOOLS

A good starter kit includes a press and other tools you’ll need to reload, but cartridge dies are sold separately.

To put all of these components together, you’re going to need a reloading press. The press will help align and properly seat a bullet in a shell casing. But you’re also going to need some extra stuff, which is why I recommend beginners buy a starter kit, like the Rock Chucker Supreme Master Reloading Kit from RCBS. In your kit, you’ll have everything you need to take casings, primers, powder, and bullets and turn them into ammunition. This includes the press, some case lube, a scale to measure powder, a powder dispenser, a loading block, and a tool to place primers in shell casings.

What you won’t have are reloading dies, which must be purchased for each cartridge you plan to reload. For example, if you want to reload .223 Remington, you need to buy .223 Remington reloading dies. Not all dies are created equal, but for your first foray into reloading, I suggest going with budget-friendly dies from a supplier like Lee.

You’ll also be missing some important tools for taking spent cartridge casings and making them usable again. Casings can stretch, so you’ll eventually need to trim them with a case trimmer. They also get dirty, so you’ll need to clean them with a case tumbler. If you’re just starting out, don’t worry. I suggest buying brand-new empty cases to handload new ammo. That way, you can figure out the basics without worrying about cleaning and prepping brass.

If you’d still like to prep old brass, you can do it without a tumbler using a wash of dish soap and water, some paper towels, and old bore brushes. Just ensure your cases are completely dry before reloading them, and continue to check the case length between reloads to confirm they’re within proper specs.

Speaking of checking case length, another essential tool that you have to buy will be a caliper. This will let you measure case length and overall cartridge length to make sure your ammo is safe to fire. You’ll also want to pick up a set of powder measuring spoons and a powder trickler. These are cheap and come in handy.

BUILD A BENCH

Reloading calls for a sturdy bench that can be kept clean and organized.

All of your reloading gear will need a place to live, and the best place is a reloading bench. A reloading bench should be sturdy. It’s ideally bolted to the floor to resist any force you put on it when running cartridges through your press.

I used butcher block to build my reloading bench. It’s dense and tough, making it a great surface for bolting on tools like a press or powder measure. You can get fancy, but the easiest way I’ve found to install a bench is to bolt the table surface to a piece of slotted angle iron affixed to the wall and run two 2x4 legs bolted to the floor.

Above or below the bench, you should account for some shelving to hold small tools and a collection of reloading dies. Organization and cleanliness are key when reloading ammo. Otherwise, it can get dangerous. Top your bench off with a good light so you can see what you’re doing and inspect ammo as you go.

You also need to consider where you’re storing gunpowder. Powder is extremely flammable and best stored in a box known as a powder magazine. The wrong way to store powder is on the shelf. You can make your own powder magazine from wood or repurpose an old fireproof file cabinet. If you make yours out of wood, make the walls a few inches thick and label the box accordingly.

HANDLOADING BASICS

Reloading is fun and rewarding, but potentially dangerous if done incorrectly. Follow these rules and reference handloading manuals to keep it safe.

Once your bench is built, it’s time to reload your first box of ammo. There are more detailed instructions for this on the web and in books. I suggest consulting a reputable source like RCBS to really understand the process and avoid any advice on the internet that isn’t backed up by an official company or publication. That said, here are the basics in seven steps to give you a rough idea of what to expect.

1. Clean and inspect the brass: Between reloads it’s important to clean and visually inspect brass cases. Look for cracked necks, dents, and general wear and tear.

2. Lubricate cases: To work through reloading dies, cases need to be lubricated.

3. Install shell holder and sizer die: Different sized shells use different sized shell holders. This is what holds a shell for the duration of the reloading process. You’ll install this on your press and properly screw in a sizing die. The sizing die will re-size the shell casing and remove the old primer.

4. Measure and prep brass: Measure cases with a caliper to see if they need trimming. If they do, you’ll need a case trimmer. This is when you will also clean out the primer pocket of a case and chamfer the edges of the case neck to better accept a bullet.

5. Prime cases: Use a priming tool to insert new primers into the case. Do this with the empty case pointing away from your face in case a faulty primer goes off.

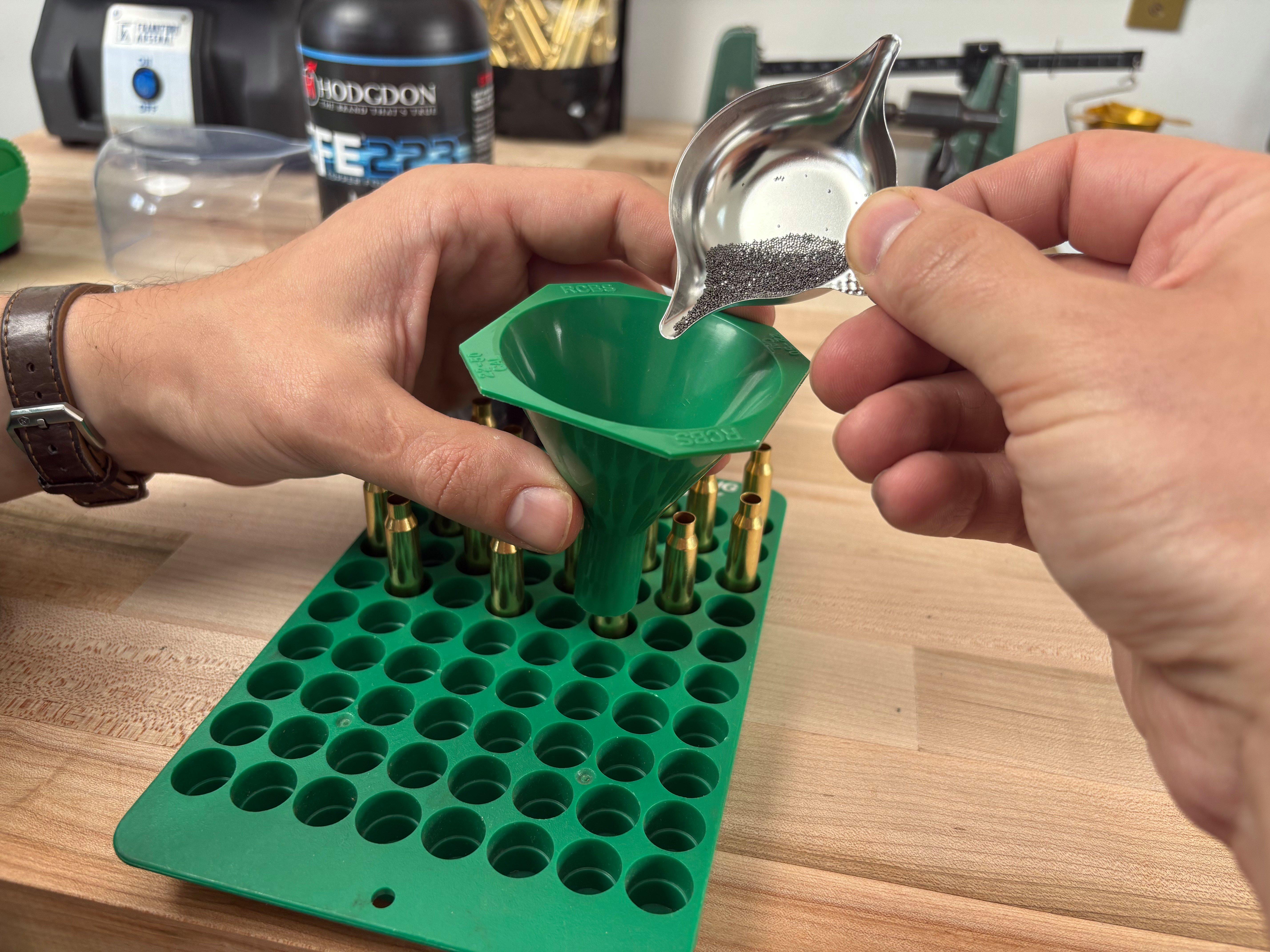

6. Charge cases: Set up your powder dispenser for the desired powder charge. Double and triple check this charge to make sure your dispenser is delivering consistent charges. I also like to weigh a random powder charge every few rounds. When your cases are all charged with powder, give the entire charging block a visual inspection. Charges should all sit at the same height within a case. If anything distracts you during this process or if you’re unsure, dump the entire batch and start over.

7. Set up seating and crimping die and load a bullet: Now you’re finally ready to load a bullet onto the case and complete the process. After setting the die up for the proper overall length (refer to your manual), place a bullet on top of the case and load the finished round. Store finished rounds in clearly marked boxes with load data and how many times the brass has been fired written on the box.

RELOADING RULES

Just as with gun safety, reloading comes with its own set of rules. Because you’re making your own ammo, it’s on you to make it properly and safely. There is room for error in reloading and those errors can be catastrophic. Keep the following dos and dont’s in mind, and you’ll be ok.

Always double and triple check cases filled with powder to avoid a double charge.

Double check that your scale is accurate every time you measure powder.

Don’t reload from data that doesn’t come from a reliable source. Internet forums are not reliable sources. Published reloading manuals are.

Never shoot somebody else's reloads. You have no idea how they were made or if someone made a mistake. By the same token, don’t give someone your reloads to shoot.

Never go beyond maximum pressure for loads.

Always keep your bench clean and free of debris.

Don’t smoke near or in the same room as your reloading bench and powder. That goes for any open flame.

Always inspect cases for abnormalities, dents, or cracks.

Destroy any ammo that was reloaded incorrectly (a bullet puller is a handy tool for this).

Don’t buy second-hand powder. You never know if someone put different powder in an old can.

Don’t reload steel cases.

Don’t reload with components of unknown origin. Yardsales are not the place to buy reloading components, especially powder.

Give reloading your full attention. If you catch yourself daydreaming, dump your powder charges and start over again. If you catch yourself daydreaming again, call it quits and come back another day.

Don’t Miss: The Best Rimfire Rounds for Small Game